Tackling a motorcycle stator test can be daunting–like walking through an electric minefield. But it doesn’t have to be! With the right knowledge and tools, you can thoroughly inspect and evaluate your stator in no time.

In this article, we’ll walk you through the steps of testing your stator–from gathering the necessary tools to reassembling your motorcycle after inspection. You’ll learn how to check the resistance of windings, measure voltage output, and even examine the pickup coil.

So don’t fret; with our guidance, you’ll be back on the road in no time!

Key Takeaways

- The stator testing process involves checking the resistance of stator windings, measuring the voltage output of the stator, testing the stator pickup coil resistance and voltage output, and inspecting electrical components for wear or damage.

- It is important to use the necessary tools such as a multimeter, wrench set, socket set, screwdriver, and wire connectors for stator testing.

- Safety precautions should be taken, including wearing protective gloves when handling electrical components and consulting the owner’s manual for the testing procedure.

- Before testing the stator, it is important to check oil levels, inspect wiring, and test the battery. Additionally, any damaged components should be replaced before turning on the motorcycle.

Gather Required Tools

Get ready to test your motorcycle stator – you’ll need the right tools!

First and foremost, you’ll need a multimeter for measuring resistance and voltage. Additionally, make sure to have other items on-hand like a wrench set, socket set, flathead screwdriver, and insulated wire connectors for replacing parts or troubleshooting errors.

For safety reasons, it’s important to wear protective gloves when handling any electrical components. Finally, an owner’s manual may prove helpful in understanding the specific testing procedure of your model.

With these tools at your disposal, you can properly diagnose potential issues with your stator.

Prepare the Motorcycle

Before you can begin the process of assessing the condition of your motorcycle’s electrical components, it’s essential to properly prepare it. Here are a few key steps you should take:

- Check oil levels: Make sure the oil is at the correct level, and that there aren’t any signs of contamination or leakage.

- Inspect wiring: Carefully inspect all wiring in and around the engine area to make sure it isn’t frayed, loose, or damaged in any way.

- Test battery: Test your bike’s battery with a voltage meter to ensure it’s still holding charge correctly.

By taking these steps before starting to test your stator, you can help ensure accurate results and be better prepared for potential issues with your electrical system down the road.

Inspect the Stator

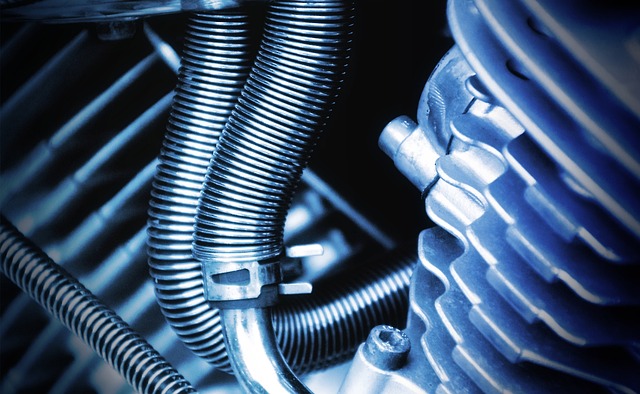

Once you’ve prepared your bike, it’s time to inspect the stator. Examine the wear of the electrical components and check their connections for any signs of corrosion or damage. Make sure to look closely at all of the parts that make up the stator, including coils, cables, wiring, and any other connectors.

Check to see if there are any frayed wires or loose connections that may be causing an issue with your stator. Additionally, look out for any signs of excessive heat, which could indicate a problem with your stator. If you notice anything wrong, then replace these components immediately to prevent further damage from occurring.

Finally, double-check all connections before turning on the motorcycle so you can ensure everything is working properly and safely.

Check the Resistance of the Stator Windings

Using an ohmmeter, measure the resistance of the stator windings to check for any irregularities. You’ll want to identify issues in order to prevent potential motor maintenance problems. Here are some key points to consider while testing:

- Check for shorts by measuring the resistance between each winding and ground.

- Make sure that the coils aren’t open circuits by using a continuity test.

- Measure the resistance of every coil with respect to all other coils.

Compare your readings against specifications provided in your manual.

This will help you determine if there’s a problem with any of your windings and allow you to troubleshoot accordingly.

Test the Voltage Output of the Stator

To ensure that your motorcycle’s stator is working properly, you’ll need to measure its voltage output. Testing the voltage output of the stator requires a few steps and tools:

| Item | Description |

|---|---|

| Multimeter | For measuring electrical current, resistance, and voltage. |

| Wrenches | For removing any covers or components from the bike. |

| Voltage regulator | For regulating the voltage produced by the stator. |

| Electrical tape or wire connectors | To secure connections between components. |

Begin by disconnecting any leads connected to the stator coils and checking with a multimeter that each coil has continuity in both directions. Next, connect an external power source to the stator coils according to manufacturer’s instructions and measure the output of each coil using a multimeter set on AC volts. Finally, reconnect any leads and check for proper operation of your motorcycle’s voltage regulator with a multimeter set on DC volts. Following these testing procedures will help you determine if your motorcycle’s stator is producing adequate voltage output for safe use.

Check the Stator Pickup Coil

Checking the stator pickup coil can be a nerve-wracking experience, but it’s essential to ensure your bike is running safely. Troubleshooting techniques for checking the stator pickup coil include:

- Check the resistance of each lead of the coil using an ohmmeter to ensure that they’re within manufacturer specifications.

- Use a multimeter to measure voltage output between each lead and ground while cranking the engine over.

- Inspect electrical components such as connectors, wiring, and terminals for any signs of wear or damage.

- Test individual components with an oscilloscope if necessary to pinpoint any issues with functionality or performance.

By following these steps, you can quickly diagnose and repair any problems with your motorcycle stator pickup coil and get back out on the road safely!

Reassemble the Motorcycle

Once you’ve diagnosed and fixed any issues with the stator pickup coil, it’s time to reassemble your bike! Begin by installing all wiring that was removed during disassembly. Make sure to double-check that it’s securely attached and there are no loose connections or exposed wires. Review your service manual for instructions on how to properly install each component.

During installation, pay close attention to the order and placement of components, as improper assembly can lead to damage or misalignment of the stator pickup coil.

When everything is put back together, start up the motor and check for proper operation. If everything looks good, you’re ready for a test ride!

Frequently Asked Questions

How do I determine if I need to replace the stator?

Assess the damage on your stator and diagnose any issues. Carefully examine it for signs of wear or damage, then use a multimeter to test the electrical connections. If problems are found, you may need to replace the stator.

How do I check the resistance of the stator windings?

To check the resistance of the stator windings, use a multimeter to measure the resistance between each contact lead. Follow testing procedures and troubleshooting tips for accurate results.

What type of tools do I need to test a motorcycle stator?

You’ll need a multi-meter to test the electrical wiring of your motorcycle stator for safety. Make sure it has the ability to measure resistance. Additionally, you may require other tools such as insulated pliers and screwdrivers.

How often should I inspect the stator?

You may think inspecting your stator isn’t important, but it’s critical for preventive maintenance and troubleshooting issues. Make sure you check it routinely to avoid any surprises down the road.

Is there a specific way to reassemble the motorcycle after testing?

When reassembling the motorcycle, make sure to follow the manufacturer’s instructions for maintenance and electrical safety. Be precise in your work and double-check connections. Pay attention to any details that could cause issues later.

Conclusion

Now that you’ve tested your motorcycle stator, it’s time to put the pieces back together. Carefully reassemble all the parts and test your machine for proper operation.

If everything looks good, you can relax knowing that your stator is in top condition and ready to go! But if something doesn’t seem quite right, don’t hesitate to take a closer look at the results of your tests – they could be the key to keeping your motorcycle running smoothly for years to come.